Cangzhou, Hebei, China

Response Time: < 24h

Response Rate: 0%

| Model No.: XT-G | Place of Origin: China |

Xin-Tian XT-G series configuration description

(the picture is for reference only, subject to the real object)

Main Technical Parameter

|

Item |

Unit |

|

|

Inside width of baffles |

mm |

3000 |

|

Maximum paper size |

mm |

1270×2600 |

|

Maximum print size |

mm |

1200×2400 |

|

Skip feeding size |

mm |

1450×2400 |

|

Minimum machining size |

mm |

320×640 |

|

Thickness of printing plate |

mm |

7.2 |

|

The thickness of the baffles |

mm |

70 |

|

Working speed |

sheets/min |

180 |

|

Design speed |

Sheets/min |

220 |

|

Topping precision |

mm |

±0.5 |

|

Slotting precision |

mm |

± 1.5 |

|

Main motor power |

KW |

37 |

|

Min slotter interval |

mm |

160x160x160x160 260x60x260x60 |

Characteristics of the whole machine:

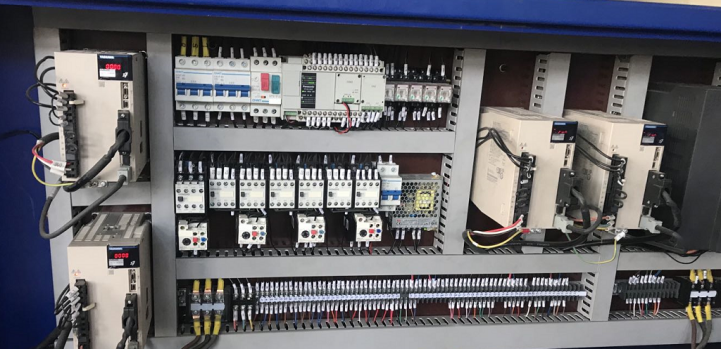

● All electrical appliances of the whole machine are made of international famous brands, with stable and reliable quality.

● Man-machine interface, computer order management, convenient operation and faster order change .

● The equipment can be maintained remotely through the network, so as to judge and solve the equipment fault quickly, improve the maintenance efficiency and reduce the maintenance cost.

● The whole machine is designed and manufactured according to high performance and high safety, and the whole machine conforms to European CE standard.

● Servo pressure free leading edge paper feeding (invention patent), truly realize pressure free paper feeding, zero pressure on paperboard, improve the carton compression resistance, servo transmission is more durable than traditional mechanical transmission mechanism, can guarantee paper feeding accuracy for a long time.

● The baffle and important parts of the whole machine are all treated by aging and tempering to eliminate the internal stress of metal;All of them are manufactured by high precision machining center and ground by CNC grinder.

● We developed advanced raw material for the panels. Steel factory produced it according our Prescription. The raw material is XN-Y15MnP,HRC 40-45,Tensile Strength is 450-630 , Yieldstrength more than 325 .It can ensure the panels not deform even the machine working everyday.

● We cut the panel by ourself and then take it to Tempering and then all of them are ground by CNC.We have 8 pcs CNC machines.

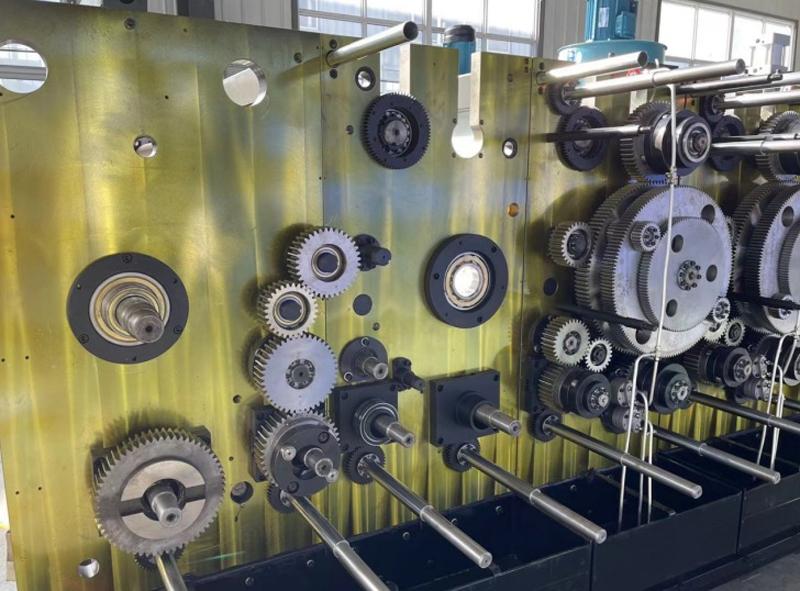

● The whole machine transmission gear are made of high quality steel, carburizing , quenching treatment and grinding treatment to sure have high precision printing for long time working.

〖1〗Material: 20CrMnTi alloy steel, carburized, Quenched and ground.

〖2〗Level 6 precision, smooth operation, low noise, hardness HRC58-62, long service life, no wear within 10 years, long-term printing registration can be achieved.

● The whole machine axles and rollers are made of high quality steel, tempered, quenching and tempering treatment; Grinding, high precision computer dynamic balance correction, rigid chrome plated on the surface.

● The whole machine adopts the servo control drive system of international famous brand, reduces the working intensity, maximizes the equipment capacity, and ensures the long-term use of high chromatic precision.

● The transmission part (shaft tooth connection) of the whole machine adopts keyless connection (expansion sleeve) to eliminate connection joint clearance, suitable for long-term high-speed operation with large torque.

● Each unit is equipped with an oil balancing device to ensure the oil balance in the oil tank of each unit.

● The main transmission parts of the whole machine are all reinforced self-aligning bearings, which have long service life, convenient maintenance and high accuracy keep the equipment running at high speed for a long time.

● The main motor adopts frequency conversion motor, frequency conversion control, energy saving, stable start, with motor start protection device.

● Unique production image processing device, in front of the machine can watch the work of the rear, so as to stop the paper feeding in case of emergency, reduce waste.

● A new status indicator light, indicating the starting status of the machine (in the form of computer progress bar), indicating the working status of the machine, indicating the fault information of the machine.

● A new status indicator light, indicating the starting status of the machine (in the form of computer progress bar), indicating the working status of the machine, indicating the fault information of the machine.

● Whole machine unit can separated one by one automatic with one button.

● SFC shaft are equipped ,(Straight Full Chromate), more hard ,smooth not get rusty.

● Hardness:HRC60°±2°; Hardness Thinckness:0.8-3mm;Surface Roughness:Ra0.10μm~Ra0.35μm

Ⅰ. Feeding Department(Servo pressure free leading edge feeding)

|

Item |

Instructions |

|

Machine seperate and together |

|

|

Servo Pressure Free Lead Edge Feeding |

|

|

Dust removal device |

|

|

Paper feeding roller |

|

|

Automatic Zeroing device |

|

Ⅱ. Printing Department

|

Item |

Instructions |

|

Printing roller |

|

|

Printing press roller |

|

|

Steel anilox roller |

|

|

Scraper system (option) |

|

|

Phase Adjusting mechanism |

|

|

Ink circulation |

|

|

Printing phase fixing device |

|

Ⅲ. Slotting Department (computer cutter)

|

Item |

Instructions |

|

Pressing device |

|

|

Slotting tool block Horizontal Adjustment mechanism |

|

|

3Slo.Slotting phase adjusting mechanism

|

|

|

Operation control switch |

|

(IV)Die-cutting department

|

Item |

Instructions |

|

Die roller (lower roller) |

|

|

Rubber pad roller(upper roller) |

|

|

Phase adjustment mechanism |

|

(Ⅴ) Stacking Department: (hydraulic waste cleaning and stacking machine)

1. Paper receiving arm

2. Vibrate for wasting removal

3. Hydraulic lifting system

4. Paper receiving baffle

Transmission gear

| Item | Instructions |

|

|

|

Key-free connection ring |

|

Computer control department

● More than 90% of the electrical appliances of the whole machine adopt international famous brands: FP Σ PC link network, paper feeding unit and slotting unit all adopt 10.4-inch color touch screen

● (Human-Computer Interface).

● Machine size computer adjustment: directly input the order size (or call the original saved order size to the computer), and perform the adjustment, the machine will automatically adjust the size of each part. 999 common orders can be saved.

● Machine zeroing, preset position and automatic plate alignment functions: printing, slotting phase zeroing and preset to ensure that all printing on the first board is inked, and the second board is basically adjusted in place, which can compensate for errors during operation.

● Frequency conversion adjustment function: the main motor runs stably and saves power. The adjustment time of printing, slotting and die cutting is shortened and the precision is high.

● CNC horizontal continuous adjustment of slotting cutter: the slotting cutter is automatically combined with the paper feeding baffle to adjust with or without trimming, and automatically adjust the paper feeding baffle to the appropriate position.

● Machine calibration parameter design: can calibrate the reference parameters, convenient for maintenance and debugging.

● Others: digital control production; real-time monitoring of slot cutter transverse and phase anti-collision knife protection; knife slot design, in the process of zeroing and automatic adjustment, the knife slot can protect the upper and lower knives to enter the slot smoothly after adjustment to protect the knives; ink shortage alarm; multi-point operation control; speed 80, 120,180, 200 cruise.

Motor list

|

Name |

Place of Origin |

Specifications |

Quantity |

|

I. Paper Feeding Department |

|||

|

1 Main Motor |

Qufu,Shandong |

Variable frequency motor 37KW |

1 |

|

2 Each units together and seperated |

Taizhou,Zhejiang |

1.5KW 1/120 Gear motor |

1 |

|

3 Left and right side baffle adjustment |

Taizhou,Zhejiang |

0.18KW 1/10 Gear motor |

2 |

|

4 Back baffle adjustment |

Taizhou,Zhejiang |

0.18KW 1/25 Gear motor |

1 |

|

5 Adsorption fan |

Baoding Fan |

7.5KW Frequency |

2 |

|

6 Servo motor |

Yaskawa,Japan |

4.4KW |

4 |

|

7 Servo control |

Yaskawa,Japan |

4.4KW |

4 |

|

7 Dust removal fan |

YingFa,ShangHai |

2.2KW |

2 |

|

II. Printing Department |

|||

|

1Phase adjustment |

Taizhou,Zhejiang |

0.37KVariable frequency 1/15 Gear motor |

1/color |

|

2 Rubber roller idling |

Shengbang,Taiwan |

0.75KW 1/40 Gear motor |

1/color |

|

3 Roller shift |

Taizhou,Zhejiang |

0.15KW 1/80 Gear motor |

1/color |

|

III. Slotting Department |

|||

|

1 Phase adjustment |

Taizhou,Zhejiang |

0.37KWVariable frequency 1/15Gear motor |

1 |

|

2Slotting adjustment |

Shengbang,Taiwan |

0.4KW 1/43 Gear motor |

5 |

|

3Box height adjustment |

Taizhou,Zhejiang |

0.37KW 1/30 Gear motor |

1 |

|

IV. Other Instructions |

|||

|

1Bearing |

Harbin |

Other parts |

All |

|

2Bearing |

NSK,Japan |

Main parts |

All |

|

3Contactor |

Siemens, Germany |

|

All |

|

4.Button |

Siemens, Germany |

|

All |

|

5.Leading edge encoder |

Peugeot, Germany |

|

All |

|

6. PLC |

Panasonic,Japan |

|

All |

|

7.Encoder |

Koyo,Japan |

|

All |

|

8. Touch screen |

MCGS |

|

All |

|

9.Photoelectric switch |

Omron, Japan |

|

All |

|

10.Proximity switch |

Omron, Japan |

|

All |

|

11.Relay |

Omron, Japan |

|

All |

|

12.Solenoid valve |

Jinqi,Taiwan |

|

All |

|

13.Frequency converter

|

Taida,Taiwan |

|

All |

|

14.Keyless connecting ring |

Xianyang,Shanxi |

|

All |

|

15.Pneumatic diaphragm pump |

Jinchangjiang ,Wuhan |

|

All |

|

16.Clutch |

Xianyang,Shanxi |

|

All |

|

17.Pneumatic components |

Hengyi,Tianjin |

|

All |

|

19.Ceramic anilox roller |

Yuexin,guangdong |

|

All |

|

20.Doctor blade |

LiJian,guangdong |

|

All |

|

21.Ink rubber roller |

JiZhou, HeBei |

|

All |

|

22.Rubber cover |

Italy |

Policart |

All |

|

23.Slotting knife |

Qingdao Qifeng |

|

All |

Note: the air compressor is provided by the customer.

![]()