Cangzhou, Hebei, China

Response Time: < 24h

Response Rate: 0%

| Model No.: XT-D | Place of Origin: China |

CANGZHOU XINTIAN PACKING MACHINERY.CO.LTD

Contact

|

Customer |

Supplier |

|

Company: |

Company: CANGZHOU XINTIAN PACKING MACHINERY.CO.LTD |

|

Contact: |

Contact:Ms.Hellen |

|

Mobile: |

Mobile:0086-18682443934/ 13930754007 |

|

Tel: |

Tel:0086-317-7751077 |

|

Add: |

Add:291.5kolimeter 104 country road south town DongGuang County hebei province China |

XT-D Printing Slotter Die-cutter Striper with stacker Machine

(Configuration description)

Characteristics of the whole machine:

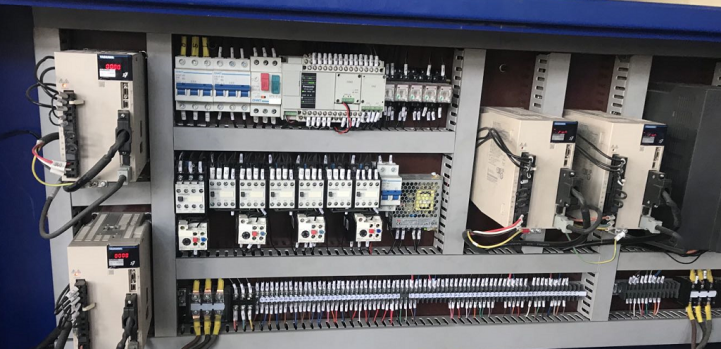

¤All electrical appliances of the whole machine are made of international famous brands, with stable and reliable quality.

¤Man-machine interface, computer order management, convenient operation and faster order change .

¤The equipment can be maintained remotely through the network, so as to judge and solve the equipment fault quickly, improve the maintenance efficiency and reduce the maintenance cost.

¤The whole machine is designed and manufactured according to high performance and high safety and the whole machine conforms to European CE standard.

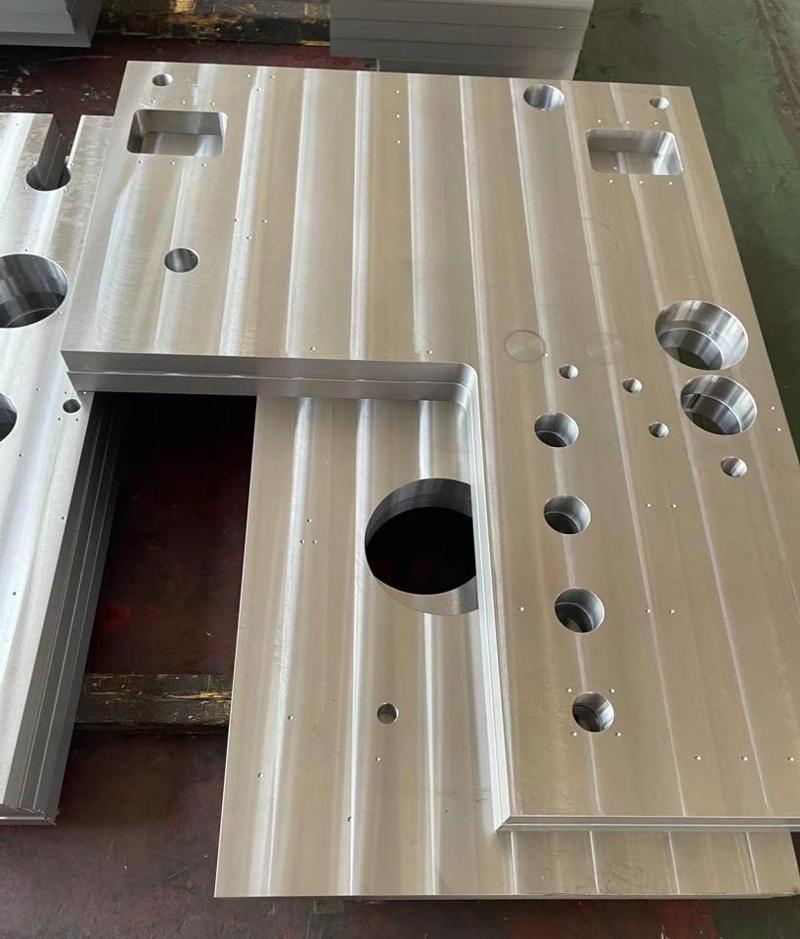

¤The baffle and important parts of the whole machine are all treated by aging and tempering to eliminate the internal stress of metal.

XinTian developed advanced raw material for the panels. Steel factory produced it according our Prescription. The raw material is XN-Y15MnP,HRC 40-45,Tensile Strength is 450-630 , Yieldstrength more than 325 .It can ensure the panels not deform even the machine working everyday.

We cut the panel by ourself and then take it to Tempering and then all of them are ground by CNC.We have 8 pcs CNC machines.

¤The whole machine axles and rollers are made of high quality steel, tempered, quenching and tempering treatment; Grinding, high precision computer dynamic balance correction, hard chrome plated on the surface.

¤The whole machine transmission gear are made of high quality steel, carburizing , quenching treatment and grinding treatment to sure have high precision printing for long time working.

〖1〗Material: 20CrMnTi alloy steel, carburized, Quenched and ground.

〖2〗Level 6 precision, smooth operation, low noise, hardness HRC58-62, long service life, no wear within 10 years, long-term printing registration can be achieved.

¤The transmission part (shaft tooth connection) of the whole machine adopts keyless connection (expansion sleeve) to eliminate connection joint clearance, suitable for long-term high-speed operation with large torque.

¤Spray lubrication .Each unit is equipped with an oil balancing device to ensure the oil balance in the oil tank of each unit. Whole machine’s bear has filling aperture,easy to filling.

¤The main transmission parts of the whole machine are all reinforced self-aligning bearings, which have long service life, convenient maintenance and high accuracy keep the equipment running at high speed for a long time.

¤The main motor adopts frequency conversion motor, frequency conversion control, energy saving, stable start, with motor start protection device.

¤Unique production image processing device, in front of the machine can watch the work of the rear, so as to stop the paper feeding in case of emergency, reduce waste.

¤A new status indicator light, indicating the starting status of the machine (in the form of computer progress bar), indicating the working status of the machine, indicating the fault information of the machine.

¤Whole machine unit can separated one by one automatic with one button.

¤ SFC shaft are equipped ,(Straight Full Chromate), more hard ,smooth not get rusty.

.Hardness:HRC60°±2°; Hardness Thinckness:0.8-3mm;Surface Roughness:Ra0.10μm~Ra0.35μm

Computer control department

XT-D Main Technical Parameter:

|

Item |

Unit |

Style 1600×2800 |

|

Inboard width size |

㎜ |

2800 |

|

Max paper size |

㎜ |

1670×2600 |

|

Max printing size |

㎜ |

1600×2400 |

|

Skip feeding size |

㎜ |

1850×2400 |

|

Min finish size |

㎜ |

400×720 |

|

Thickness of printing plate |

㎜ |

7.2 |

|

Speed |

PCS/min |

0-150 |

|

Printing precision |

㎜ |

4 color ±0.5 |

|

Slotting precision |

㎜ |

±1.5 |

|

Max slotting depth |

㎜ |

300 |

|

Min slotting interval |

㎜ |

Close wise: 180×180×180×180 280×80×280×80 |

I. Feeder Department

|

Name |

Note |

|

Lead edge feeding system |

|

|

Dust removal device |

The brush of the paper feeding part and the upper air suction and dust removal device can largely remove the impurities on the printing surface of the paperboard and improve the printing quality. |

|

Paper feeding roller |

|

|

Automatic zeroing device |

|

|

Function |

|

II. Printing Department

1.

|

Name |

Note |

|

Printing roller (Plate roller) |

|

|

Vacuum transfer |

|

|

Ceramic anilox roller |

|

|

Rubber roller |

|

|

Phase adjustment mechanism |

|

|

Ink circulation |

|

|

Printing phase fixing device |

|

2.

|

Function |

|

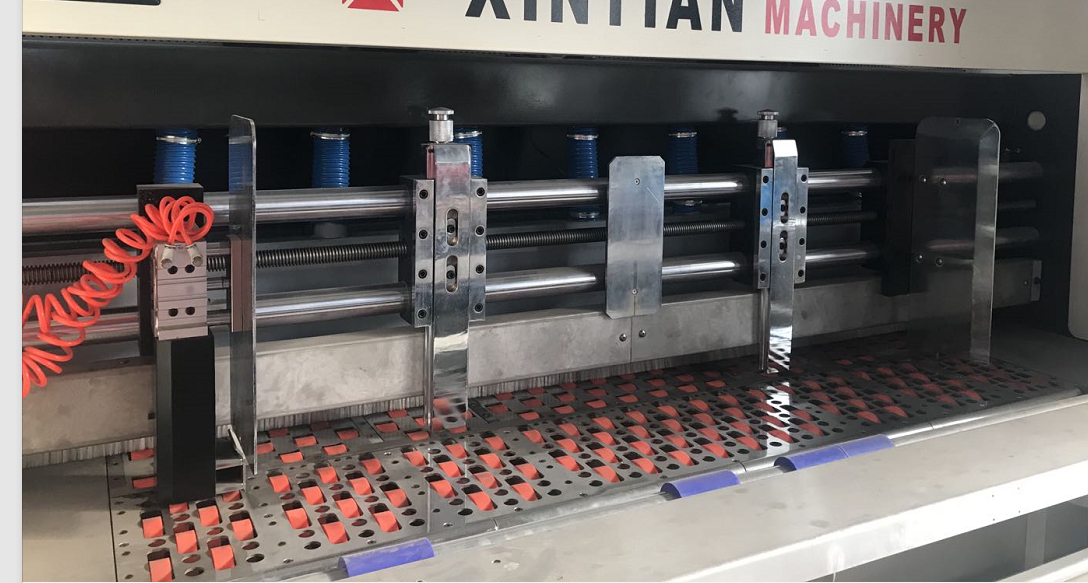

III. Slotter Department

Single shaft slotter motorized

1.Crease device

〖1〗The axle diameter is Φ 110 ㎜, the surface is ground, hard chrome plated, and the movement is stable.

〖2〗Do balance correction and run smoothly. Do balance correction and run smoothly.

〖3〗The dial of the crease wheel gap is manually adjusted, and the adjustment range is 0~12mm.

2.Slotting tool seat transverse adjustment mechanism

〖4〗The axle diameter is Φ 124 ㎜, the surface is ground, plated with hard chrome, and moves smoothly.

〖5〗The width of the slotting knife is 7㎜.

〖6〗Alloy steel material is heat-treated and ground tooth-shaped slotting knife, with excellent hardness and toughness.

〖7〗The edge trimming knife is made of alloy steel after heat treatment, with a sharp edge and high precision.

〖8〗The position of the crease wheel and the slotting knife seat is adjusted horizontally, and the electromechanical joint adjustment is adopted.

3.Slotting phase adjustment mechanism

〖9〗Planetary gear structure.

〖10〗Slotting phase electric digital 360° adjustment. (Running and stopping can be adjusted)

IV. Die-cutter Department

1. The die-cutter department has an independent servo driver.

2.

|

Name |

Note |

|

Die roller (lower roller)

|

|

|

Upper roller

|

|

V. Stacking Department: (hydraulic waste cleaning and stacking machine)

1、Paper receiving arm

〖1〗Manual or automatic operation can be selected.

〖2〗Paper receiving arm drive belt, adjust the tightness independently, regardless of the length of the belt.

2、Bed hydraulic lifting system

〖1〗Driven by strong chain.

〖2〗 Stacking height: 1600 mm.

〖3〗The bed is raised and lowered by a hydraulic lifting system, which keeps the bed in a fixed position and does not slide.

〖4〗A safety protection device is installed to make the bed and table rise and fall under the control, ensuring the safety of operators.

〖5〗Flat wrinkle climbing belt to prevent the cardboard from sliding.

3、Paper receiving baffle

〖1〗Pneumatic action paper receiving baffle, when the paperboard is stacked to a predetermined height, the paper receiving support plate automatically extends to hold the paperboard.

〖2〗 Manually adjust the position of the back baffle.

Main parts list

|

|

Parts |

Picture |

Parameter |

Brand |

Description |

|

1 |

Frequency Transformer |

|

22KW |

DELTA |

Frequency range:0-599HZ |

|

2 |

Relay |

|

|

OMRON |

MY2N-GS 220/240VAC |

|

3 |

Electric Appliance |

|

|

ABB |

|

|

4 |

PLC |

|

|

Panasonic |

|

|

5 |

Encoder |

|

|

Germany |

|

|

6 |

Touch screen |

|

|

MCGS |

|

|

7 |

Button |

|

|

SIEMENS |

|

|

8 |

Main moter |

|

15-30KW |

Qufu |

Variable frequency motor |

|

9 |

Servo motor |

|

5KW |

Anka |

|

|

10 |

Die-cutter Servo motor |

|

22KM |

Anka |

|

|

11 |

Servo driver |

|

4/5.5KW |

Anka |

|

|

12 |

Fan |

|

11KW |

JINGTAIDA |

2300r/min |

|

13 |

Fan motor |

|

11KW |

HENGSHUI YONGSHUN |

MODEL:YE2-160M1-2 |

|

14 |

Gear reducer |

|

RATIO:7.5 |

SUNCARVE |

MODEL:RV040 |

|

15 |

Distributing Ink Motor |

|

0.75KW |

TaiWan ChengBang (CPG) |

1/120 Reduce Motor |

|

16 |

Split Motor |

|

1.5KW |

TaiWan ChengBang (CPG) |

1/120 Reduce Motor |

|

17 |

Wallboard |

|

|

Y15mmP |

Thickness 50㎜ |

|

18 |

Printing roller |

|

Φ 406㎜ |

Hebei |

45#Steel Rolling, Welding,Computer dynamic balance correction, Grinding and Hard Chromium Plating, Forging,Heating, 60mm Interface |

|

19 |

Cearmaic Anilox Roller |

|

Φ 212㎜ |

GuangDong |

High quality seamless steel pipe with thick thickness, surface ceramic fine grinding, laser carving mesh grain. |

|

20 |

Rubber roller |

|

Φ 195㎜ |

Hebei |

Dynamic balance correction, double disc double welding,the connection between shaft and shaft head adopts the processing method of hot inlay |

|

21 |

Underprint roller |

|

Φ 124㎜ |

Hebei |

Dynamic balance correction,hard chromium plating |

|

22 |

Die-cutting roller |

|

upper roller Φ 388.9㎜ |

Hebei |

The surface of cast iron material is ground and hard chrome plated. Balance correction, increase operation stability. |

|

23 |

Feeding up and down roller |

|

up roller Φ 86㎜ down roller Φ124㎜ |

Hebei |

The surface is ground and hard chrome plated. |

|

24 |

Rubber |

|

8㎜ |

Italy Policart |

|

|

25 |

Self-aligning Bearing |

|

|

NSK |

Anilox roller and rubber roller with NSK brand |

|

26 |

Clutch bearing |

|

|

Henan

|

|

|

27 |

Transmission gear |

|

|

20CrMnTi |

|

|

28 |

Pneumatic Components |

|

|

HengYi |

|

|

29 |

Ink pump |

|

|

WuHan JINCHANGJIANG |

|

|

30 |

keyless connection ring |

|

|

XianYang |

|

|

31 |

Overrunning clutch |

|

|

XianYang |

|

|

32 |

Electron Magnetic Valve |

|

|

TaiWan |

DC24V 0.12A |

|

33 |

Dust Removal Fan |

|

|

ShangHai |

|

Equipment acceptance standard

Ⅰ. The supplier guarantees that the machine sold can be fully suitable for the subsequent processing procedures of A, B, C, E corrugated three-layer board and A, B, C, E combined five-layers corrugated board.

Ⅱ. Test conditions

1. Corrugated board with good quality, dimension standard and bending degree shall not exceed 0.015mm bending coefficient. (this coefficient refers to the difference in the bending height of the board when the board width is X or Y).

The test board is proportional to this coefficient, but the maximum bending shall not exceed 18mm.

For example:

|

Board width |

Bending height |

Bending coefficient |

|

400㎜ |

6㎜ |

0.015 |

|

600㎜ |

9㎜ |

0.015 |

|

1200㎜ |

12㎜ |

0.015 |

2. The printing plate should be of good quality and no stain, printing plate is set.

3. Provide the size range of the cardboard for testing: any size within the specification range of the mechanical design.

4. Speed measurement:

(1) Cardboard according to machine rating:

Maximum length and width 60% (machine speed)

Minimum length and width 60% (machine speed)

When the size is 1/2, the speed can reach 80% of the design speed

If it is necessary to add drag bar for printing, the above conditions can ensure the accuracy.

5. Accuracy:

(1) Paper feeding accuracy: the accuracy range of the machine running direction is ± 1mm.

(2) Printing accuracy: the accuracy range of the second color to the fourth color is ± 0.5mm with the first color as the reference point.

(3) Die cutting accuracy: the accuracy range of the machine running direction is ± 1.5mm.

![]()