Cangzhou, Hebei, China

Response Time: < 24h

Response Rate: 0%

| Model No.: XT-D | Place of Origin: China |

CangZhou XinTian Packing Machinery Co., Ltd.

Contact

|

Customer |

Supplier |

|

Company: |

Company: CangZhou XinTian Packing Machinery Co.,Ltd |

|

Contact: |

Contact:Ms.Elena |

|

Mobile: |

Mobile:0086-13711559615/17736996005 |

|

Tel: |

Tel:0086-317-7751077 |

|

Add: |

Add:291.5kolimeter 104 country road south town DongGuang County hebei province China |

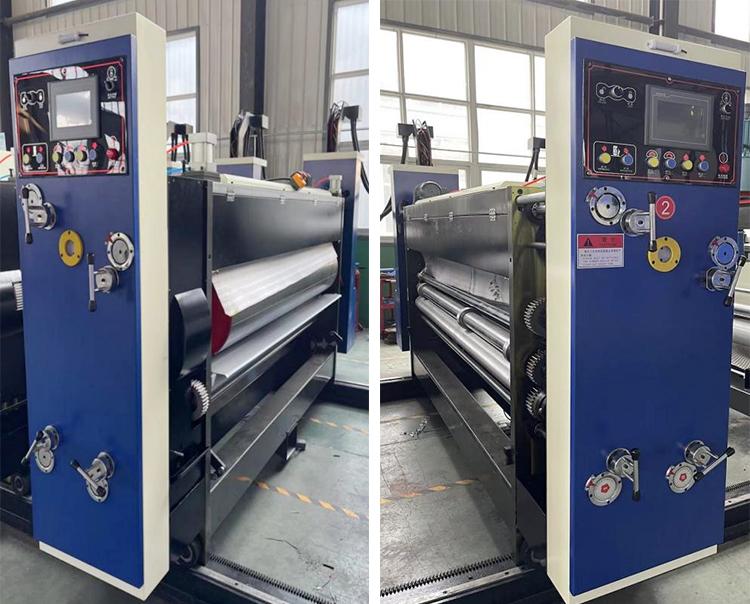

XT-D- FLEXO PRINTER DIE CUTTER WITH STACKER MACHINE

I. Characteristics of the whole machine:

1.The whole machine electrical appliances and computer software are all internationally famous brand , and the quality is stable and reliable.

2.Adopt man-machine interface, computer order management, easy to operate, change the order more.

3.The device can be remotely maintained through the network to quickly determine and resolve equipment failures , improve maintenance efficiency , and reduce maintenance costs.

4.The whole machine is designed and manufactured according to high performance and high safety , and the whole machine conforms to European CE standards.

5.Servo pressure –free leading edge paper feeding (invention patent), truly realizes pressure –free paper feeding , zero pressure on paperboard. Improve the compression resistance of the carton , the servo drive is more durable than the traditional mechanical gearbox mechanism, and can ensure the accuracy of paper feeding for long time.

6.The whole machine wall panel and important parts are treated by aging treatment, tempering to eliminate metal internal stress; using high-precision machining center, CNC grinding machine grinding.

7.The whole machine shaft and roller are made of high quality steel, temperate , quenched and tempered ; grinding processing , high precision electricity balance correction , hard chrome plating .

8.The whole machine transmission gear is made of high-quality alloy-steel, carburized and quenched, and processed by grinding. Ensure long-term use of color registration accuracy.

9.The transmission parts of the whole machine (the joint of the shaft teeth) is connected by a key less connection ( expansion sleeve) , The gap is suitable for long-term high –speed operation with high torque.

10.Each unit is equipped with an oil balance device to ensure the balance of oil in each unit’s fuel tank.

11.The important transmission parts of the whole machine are all equipped with reinforced self-aligning bearings, which have long service life and convenient maintenance, ensuring long-term high-speed operation of the equipment.

12.The main motor adopts variable frequency motor, frequency conversion control, energy saving, stable start, and motor start protection device.

13.The unique production of image processing device can view the rear working condition in front of the machine, so as to stop the paper feeding in case of emergency, reduce waste.

14. A novel status indicator that indicated the start-up status of the machine (in the form of a computer progress bar), indicates the operating status of the machine, and indicates fault information for the machine.

II. Main Technical Parameter:

|

Item |

Unit |

style |

|

Inside width of baffles |

mm |

3200 |

|

Paper size |

mm |

1670×3000 |

|

Effective printing |

mm |

1600×2800 |

|

Min machining size |

mm |

400×720 |

|

Thickness of printing plate |

mm |

7.2 |

|

Max. speed |

sheets/min |

150 |

|

Main motor power |

KW |

15~30 |

|

Total power |

KW |

40~55 |

|

Weight |

T |

17-20 |

|

Topping precision |

mm |

±0.5 |

|

Slotting precision |

mm |

± 1.5 |

III. Feeder unit with Servo motor drive

1. New Model light pressure Lead edge feeding system(Patent product)

〖1〗Suction secondary paper feeding (Fan Motor: 11.5KW) can adjustment the air volume according to the different conditions of cardboard bent, ensure smooth paper feeding.

〖2〗Up and down cardboard was used cylinder promote , which was rapid and save effort.

〖3〗Choice the new model light pressure lead edge feeding cardboard system, which can reduce friction when cardboard feed into machine ,it can improved cardboard compression capability.

〖4〗Side board and back board position adjustment by electric , and front board gap adjustment by electric ,.

〖5〗Skip feeding position ( Depend on require and choice the continue or skip feeding )

〖6〗Counter for cardboard , show the production quantity.

2. Dustbuster System

〖7〗Brush Dustbuster device , it have a brush in the front of kick feeding , it can clearance a lot of the dust on the cardboard , it can improve the quality for printing.

3. Feeding roller

〖8〗External dia.: ¢86㎜

〖9〗Solid steel: wrapped by wearable rubber and balance corrected

〖10〗Down feed roller: ¢156mm.Hard Chrome plated and embossed

〖11〗Dial between the feed rolls: manually adjusted; clearance arrange: 0~12㎜

4. Automatic Return To Zero

〖12〗Paper feeders, printers and notches: can electrically and automatically return to zero position.

〖13〗Automatically return to zero for general paper box and can move to correct position after two pieces of trial printing to reduce waste.

IV.

Printing unit

1.Printing roller (printing plate roller)

〖1〗External dia.: ¢521.6㎜ (¢536㎜involving printing)

〖2〗Steel tube face: abraded and hard Chrome plated.

〖3〗Balance corrected and stable in operation .

〖4〗Print-rolling shaft: in the style of fixed ratchet wheel

〖5〗Hanging slot for the whole +half printing fit for 10㎜×3㎜ bar

〖6〗Loading and unloading printing plate: electrically controlled for bi-directions turn and foot-switched

2.Printing pressure roller

〖1〗External dia.:¢176㎜.

〖2〗Steel tube face: Abraded and hard Chrome plated,steel roller thickness 22mm.

〖3〗Balance corrected and stable in operation.

〖4〗Dial between the feed rolls: manually adjusted, clearance arrange:0~12㎜.

3.Upper and down rollers

〖1〗Upper roller: External dia.:¢86㎜,thickness 18mm , Solid steel: 3 feeding rings accompanied

〖2〗Down roller: External dia.:¢124㎜,thickness 18mm ,Steel tube (Solid steel) face: abraded and hard Chrome plated.

〖3〗Dial between the feed rolls: manually adjusted, Clearance arrange :0~12㎜.

4.Steel anilox roller

〖1〗External dia.:¢212㎜.

〖2〗Steel tube face, Netted suppressed .Abraded and hard Chrome plated.

〖3〗Balance corrected and stable in operation.

〖4〗Each mesh: Printing unit with 200,220,250 option.

〖5〗Auto air-pressured lifting devices accompanied with paper feeding system (The net roller goes down to contact with the printing plate during paper feeding, and during feeding stopped, it goes up apart from the printing plate.)

〖6〗With V-Shaped Overrunning clutch: to make ink distribution and clear ink more convenient.

5.Ceramic Anilox roller( Option) Rubber roller

〖1〗External dia.:¢212㎜.

〖2〗Steel surface coating ceramic grinding,laser engraving textured.

〖3〗Mesh have 280, 300, 320 , 350. 360.Option .

〖4〗Ceramic anilox have wear and long life than steel model.

6.Rubber Roller

〖1〗External dia.:¢195㎜.

〖2〗Steel surface coating wear rubber wrapped and do balance correction.

〖3〗High special rubber grinding ,good ink transfer effect.

7.Phase-Adjusting Mechanism

〖1〗Structured in planet-gears.

〖2〗Printing-phase: adjusted with 360° for operating, pausing

〖3〗Horizontal distance: adjusted with NC, Adjustment distance total 14㎜

8.Water-And-Ink Circulation Mechanism

〖1〗Pneumatic diaphragm pump: stable in conveying ink and handy in operation and maintenance

〖2〗Printing ink filtrating net: to filtrate impurity

〖3〗Plastic ink slot

9.Printing-Phase Fixing Mechanism

〖1〗Cylinder braking mechanism

〖2〗Braking mechanism: controls the turning of machine to keep stable of the wheel position when the machine is disassembled or the phase is adjusted.

V. Die cutting part (standard die cutter unit)

A. Die roller (lower roller)

1.Outer diameter is¢487mm (without cluding cutter die).

2.The surface of cast iron material is ground and hard chrome plated.

3.Balance correction, increase operation stability

4.Cutting die 100 x 100mm fixed screw hole spacing.

5.Applicable to die height of 25.4mm.

6.Thickness of wood template: 16 ~ 18 mm (three floors board with) 13 ~ 15 mm (five floors board with).

B.Rubber pad roller (upper roller)

1.Outer diameter is ¢388.9mm

2.The surface of cast iron material is ground and hard chrome plated.

3.Balance correction to increase operation stability.

4.Adjust manually the gap with the cutter mould rollers.

5.The thickness of the rubber pad is 8mm (outer diameter is ¢406.9mm), and the width is 250mm.

6.Mechanical horizontal 60mm traveling device, die-cutting equalizer compensates automatically the linear speed, which can make the die-cutting rubber pad wear evenly and prolong the service life.

C.Phase adjustment mechanism

1.Planetary gear construction

2.Die cutting phase electric digital 360 ° adjustment (operation and stop can be adjusted).

3.Adjust motorized the horizontal position, with a total adjustment distance of 14mm.

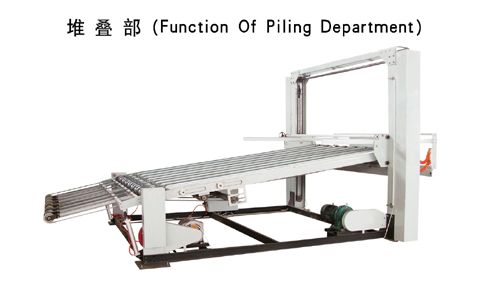

VI. STRIPPRER AND STACKER

1、The paper pick arm

a.Can be operated manually or automatically.

b.The paper arm drive belt adjusts the tightness separately, no matter how length of the belt.

2、Hydraulic lifting system

a.Powerful chain

b.he stack height is 1600mm

c.The bed adopts a hydraulic lifting system, and the bed can be kept in a fixed position without falling.

d.Add safety protection device to make the bed lift in the control to ensure the safety of the workers.

e.Plane wrinkle climbing belt to prevent the cardboard sliding down.

3、The paper baffle

f.Pneumatic action paper baffle, when the cardboard is stacked to a predetermined height, the paper tray automatically extends to hold the cardboard.

g.The position of the tailgate is Manually adjusted the back baffle position..

List of motors and important parts:

|

Name |

Photo |

Model |

brand |

mark |

|

Bearing |

|

|

Japan “NSK” |

Rubber roller and anilox roller |

|

Touch screen |

|

10’’ |

MCGS |

whole |

|

PLC |

|

|

Panasonic |

whole |

|

Contractor |

|

|

SIEMENS |

whole |

|

Button |

|

|

SIEMENS |

whole |

|

BREAKER |

|

|

SCHNEIDER |

whole |

|

Main A/C invert drive |

|

22-37KW |

Delta |

whole |

|

Servo motor |

|

7-10KW |

Anka |

whole |

|

Servo controller |

|

7-10KW |

YASAKAWA |

whole |

|

Encoder |

|

|

Japan KOYO |

whole |

|

Proximity switch |

|

|

Japan“OMRON” |

Whole |

|

Photoelectric switch |

|

|

Japan“OMRON” |

Whole |

|

Valve |

|

|

Taiwan “MINDMAN” |

whole |

|

Relay |

|

|

Japan“OMRON” |

whole |

|

Main motor |

|

22-37KW |

QUFU |

Frequency motor |

|

Feeder fan motor |

|

7.5KW |

GAOBEIDIAN |

2 |

|

Feeder fan frequency motor |

|

7.5KW |

Delta |

2 |

|

Seperator motor |

|

1.5KW |

Taiwan “CPG” |

1 |

|

Ink motor |

|

0.75KW |

Taiwan “CPG” |

whole |

|

Phase reducer |

|

1:15 |

zhejiang |

whole |

|

horizontal motor |

|

0.37W |

Zhejiang |

Whole |

|

Ink motor |

|

Double head |

JICHANGJIANG |

Whole |

|

Pneumatic Component |

|

|

HENGYI |

Whole |

|

Slotter blade |

|

60˚30˚ |

Qifeng |

whole |

|

Feeder Orange wheel |

|

|

ShangHai |

whole |

|

Slotter horizontal |

|

|

“Anka” |

whole |

|

Anvil rubber |

|

|

Italy “Policart” |

whole |

|

Servo motor |

|

11.5KW |

YASAKAWA |

1 |

|

Steel anilox roller |

|

Dia.212mm |

Jiangsu |

Whole |

|

Ceramic anilox roller |

|

Dia.212mm |

shangyun |

whole |

|

Rubber roller |

|

Dia.195mm |

JIZHOU |

whole |

|

Wall |

|

Y15Mnp (50mm) |

Xintian company |

Whole |

|

Gear |

|

Thickness 50mm |

6 degree precision |

20CrMnTi |

![]()